MiningOpportunity

A Pathway for CAPITAL-FREE Optimization, Makes Best-Possible Performance a Measurable Reality

A”Mining Process” for Upside Potential – It’s Time to Find Out How Good You Can Be – It’s Time to Explore for More!

For centuries, sailing ships explored for unknown lands and civilizations, and their discoveries changed the world. In this century, we continue to explore but the landscape is different. In business, there is an unexplored reservoir of dollars that you have very few numbers for… your hidden upside potential… dollars of profit that you leave on the table… dollars that your equipment and people were capable of generating but didn’t… losses that separate you from your “best possible” performance. Without data to quantify these dollars, you can’t see what’s there and you don’t understand why the dollars are trapped. Quantifying/reducing that reservoir of dollars is the key to achieving/sustaining “best possible” results. If you can’t measure “best” performance and can’t remove barriers that stand in your way, you can’t achieve “best”/optimum and MUST SETTLE FOR LESS PROFIT than your equipment and people are capable of generating!

NOW YOU CAN EXPLORE FOR MORE!

If your leadership team wants to “move beyond budget”, achieve optimization/”best possible” results, and sustain those results for the long term WITHOUT SPENDING CAPITAL, you have come to the right place!

Did you know that companies can be “in the black” and meet budget year after year and still leave millions of dollars on the table? This is possible because these dollars are NOT reported by your financial system… dollars for What’s Not Working, What’s Not Happening, What’s Missing, What’s Lost, and What’s Available But Hidden.

When leadership teams CAN’T QUANTIFY dollars they forfeit, they CAN’T ACT to convert these losses to profit. If companies DON’T KNOW THE GAP between today’s performance and “how good they can be”, they CAN’T CLOSE THE GAP and REACH “best possible” targets. Now there is a way to EXPLORE that gap and STOP your losses without capital spending.

Capital-Intensive vs. Capital-Free – Two Choices for Optimization

1) CAPITAL-INTENSIVE: LOOK OUTSIDE for New Equipment/Systems

- Traditional Approach, Narrow Scope (Focused on Equipment Productivity/Bottlenecks), Big Capital Investment

- Management’s Role: Optimize performance by purchasing/installing new equipment/systems.

- Productivity goes up, some costs may go down, excludes losses caused by processes not operating at “best” levels.

- ROI goes up but profit is not maximized because unreported hidden losses from misaligned processes partially offset new equipment gains.

2) CAPITAL-FREE: LOOK INSIDE for Hidden Profit Potential

- Proven Approach, Broad Scope (Existing Assets/Organization/Management Decision Processes), “Best” Performance Everywhere, Zero Capital

- Management’s Role: Optimize performance by ALIGNING assets, the organization, and decision processes with “best possible” goals/standards.

- Maximizes productivity with existing equipment, stops productivity losses and eliminates excess costs everywhere across a site/company.

- Millions of dollars of gains, profit maximized and gains sustained because equipment and people are performing at measurable “best” levels.

<><><><><><><><><><><><><><><><><>

MiningOpportunity: An Unforgettable Executive/Management Team Education and Development Program that “Takes the Invisible Lid Off of Performance” at Your Sites/Company… Makes “Best Possible” a Measurable Reality!

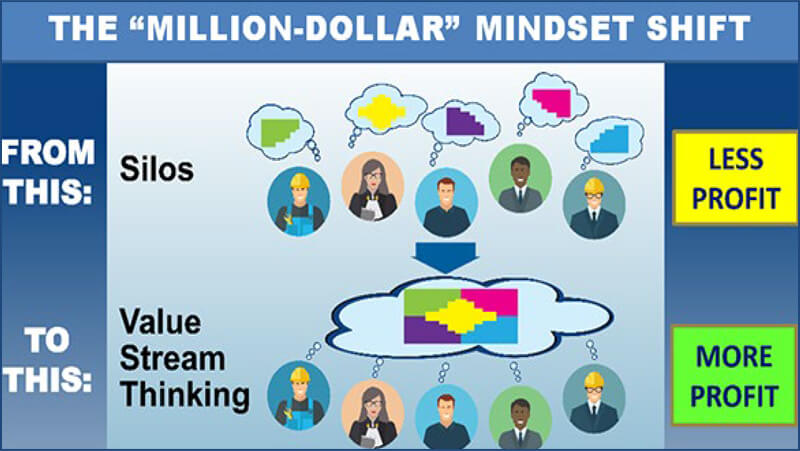

You will learn how to Optimize Performance by Finding and Fixing “Optimization Disconnects” in your Operational, Organizational and Decision-Making Processes. These disconnects exist because traditional operational/organizational/decision processes were never designed to measure or drive “best” results. These disconnects cause millions of dollars in hidden losses… your invisible upside potential… what you could have achieved but didn’t. Fixing these disconnects stops these losses and positions a company to achieve and sustain “best possible” results/optimization for the long term.

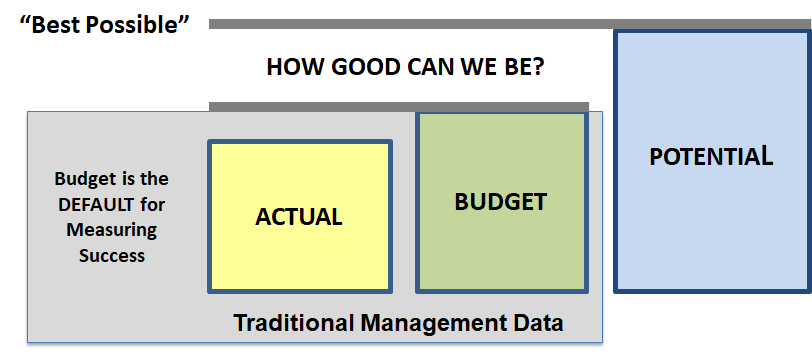

This One-Of-A-Kind Interactive Experience will give your executives and management teams new perspectives, processes, skills, tools and power to position asset management, organizational management and decision processes to achieve and sustain optimization/”best possible” performance. Actual and budget data do NOT CONTAIN metrics for “best” performance, which means you are forfeiting some of your profit and can’t achieve it even if you buy new equipment for that purpose. This development program shows you how to:

1) FIND/QUANTIFY the dollars you lost before earnings are reported… dollars that your equipment and people are capable of generating… but aren’t.

2) ALIGN/UPGRADE management processes (operational/organizational/decisions) with your goals for “best” performance: METRICS that measure “best” and quantify dollars you have been forfeiting, new STANDARDS for working at “best” levels, and STRATEGIES for fixing problems and removing barriers that prevent you from achieving/sustaining “best” performance.

Learning the Ropes…

On sailing ships of old, the captain and crew “knew the ropes”… which ropes to tighten and loosen to keep the sails aligned with the wind, avoid storms and move in the direction they wanted to go. Knowing the ropes was mandatory for sailing.

Likewise, knowing the ropes for Capital-Free Optimization is mandatory for success. In this unique educational opportunity, you will “learn the ropes”… how to look inward for hidden operating/earnings potential and convert it to profit to achieve and sustain optimization/”best” results.

A NOTE FROM KAY: On this exploration voyage, I will be your navigator and coach and your team will be the captain and crew of the ship. You will enter uncharted waters as we explore your reservoir of upside potential and hidden losses, but never fear… we will follow a proven optimization process and we will have fun along the way. We will all be in the same “optimization boat”, which means we will be doing a lot of things together and depending on each other for success.

MiningOpportunity Optimization Program: 2 Modules

FOR EXECUTIVES AND SITE MANAGEMENT TEAMS: A management education/development program that positions a company to achieve and sustain “best possible” performance/optimization for the long-term without capital spending.

1) OPTIMIZATION METRICS MODULE – Learn how to find and quantify your upside potential… the hidden losses/capacity NOT REPORTED by your financial system… linked to management processes/practices across a site or company that are NOT ALIGNED to goals/standards required for optimization. Learn how to prioritize, track, analyze, communicate and eliminate those losses, and how to manage/sustain your process of discovery.

2) OPTIMIZATION MANAGEMENT MODULE – TURNING ON THE POWER – Learn how to align and upgrade management processes for equipment, the organization and decision-making with your goals for “best” performance. CONNECT optimization metrics to management processes/practices and working relationships. REMOVE barriers and solve problems preventing your success. Alignment allows your people to work at their best level and stops losses.

SIMILAR TO A MINING PROCESS – Barriers that hide/trap losses are removed (similar to overburden) and hidden losses in your profit potential reservoir (similar to ore) are extracted/depleted. When “best” is your goal, your target recovery for each loss in your reservoir is often 100% because you remove the source of the loss to stop the loss.

Content Summary – 5 Parts (See the TEAM TRAINING PAGE for more detail)

PART 1: OVERVIEW – EXPECTATIONS FOR YOUR JOURNEY: Your training begins with a 10,000 foot view of your optimization voyage… what to look for, surprises you may discover, hazards that can stop your progress, changes you will experience along the way, and what your destination looks like. We review the content of BOTH MODULES and talk about DEFINITIONS, EXPECTATIONS, PERSPECTIVES, METRICS, BARRIERS/BOTTLENECKS, and MANAGEMENT SYSTEM LINKS (the Big Picture).

PART 2: OPTIMIZATION METRICS MODULE – QUANTIFYING YOUR UPSIDE POTENTIAL

TOPICS COVERED: Mathematical Proof That Potential Exists, Finding/Valuing/Analyzing Hidden Losses, Connecting Metrics to Performance, Communicating Hidden Losses/Capacity Visually and Orally, Managing the Discovery Process

PARTS 3-5: OPTIMIZATION MANAGEMENT MODULE – TURNING ON THE POWER

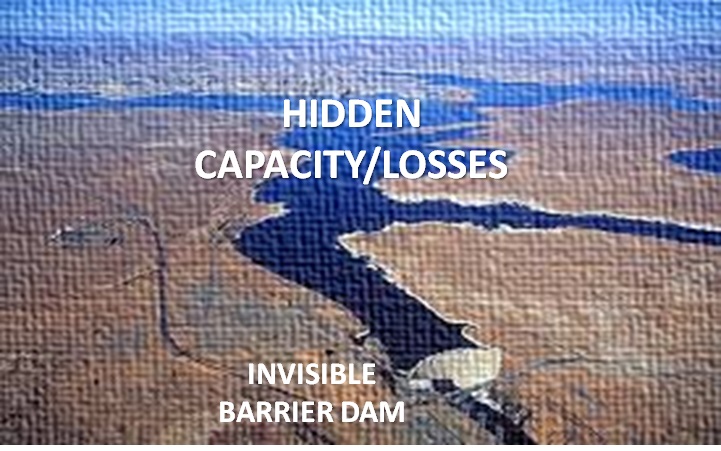

3) “HAZARD TRAINING” FOR OPTIMIZATION – Recognizing and Removing Barriers that Trap Profit, Minimizing Risk of Loss

TOPICS COVERED: Understanding Your Barrier Dam, Quantitative/Qualitative Barrier Types, Barrier Removal Strategies, Improvement Sabotage, Removing Barriers to Minimize Your Risk of Loss, Creating a Comfort Zone for Change

4) OPTIMIZATION MANAGEMENT MODULE – ALIGNMENT

UPGRADE with Metrics and Standards for “Best” Performance, REMOVE Barriers and Fix Problems that Stand in Your Way

TOPICS COVERED: ALIGNING THE ORGANIZATION AND MANAGEMENT PROCESSES to your goals/standards for “best” performance. This step explores for Misalignments. If found, you set new standards for excellence, fix the misalignments and give your people simple tools to minimize/eliminate future losses. Alignment removes the source of hidden losses and stops losses… which adds and sustains more profit without capital spending.

5) TRAIN TO SUSTAIN: Strategies/Tactics for Sustaining Your Team’s Learnings and Financial Gains for the Long Term

<><><><><><><><><><><><><><><><><>

How is Capital-Free Optimization Different From Improvement?

Improvement Process: Incrementally increases today’s performance in the midst of invisible barriers that sabotage success. Production process barriers are often removed, but management system barriers that prevent change are seldom removed… barriers that will jeopardize project gains and prevent the sustainability of improvement initiatives. This is one cause of “flavor-of-the-month” initiatives.

Capital-Free Optimization: quantifies the gap between today’s performance and the “BEST” you could do. You gain access to your reservoir of hidden profit potential by removing the barriers that stand in your way. You know how good you can be before you decide on a plan to reach your target! When you know the size of this gap, your strategy changes. It’s not about getting better… it’s about GETTING IT ALL so you can optimize performance…. a different way to THINK… a different way to OPTIMIZE… a different way to MAKE MONEY… a different way to CHANGE!

OPTIMIZE BEFORE START-UP: The Perfect Optimization Opportunity

New operations have a one-time opportunity to position the site to achieve “best-possible” performance starting on Day One of production. It is possible to choose and integrate optimization metrics strategically into asset management, the organization and management processes to make “best possible” the way you measure, manage, work and do business over LOM. This means that management has aligned management/decision processes with optimization, which positions a site to minimize/eliminate losses over LOM. Executives and site management will NEVER KNOW how many millions of dollars will be saved, but they WILL KNOW they have a system in place designed to minimize risk of loss and maximize the flow of profit generated by the entire site.

<><><><><><><><><><><><><><><><><>

“BEST POSSIBLE” PERFORMANCE TESTIMONIALS

“I am happy because you are teaching my people to think like I do!” J. Huang, CEO, Chinalco Copper, Peru

“Kay helped our managers see the world differently and zero in on the best value opportunities…

Kay knows how to change a culture.” Richard Robison, Senior Vice President, Peabody Energy

MiningOpportunity Teaches Executives and Management Teams how to Quantify what “Best Possible” looks like and Provides Strategies/Tactics for Removing Barriers and Bottlenecks Preventing Them from Achieving It… without Capital Spending. There is no other educational management team training program like this!

It’s Time to Stop leaving Money on the Table. It’s Time to Talk to THE EXPERT with 25 YEARS OF EXPERIENCE in “BEST POSSIBLE” PERFORMANCE and OPTIMIZATION MANAGEMENT!

We would be happy to answer your questions about this unique one-of-a-kind training program.

480-545-9095, 480-223-2230

Email: KaySever@MiningOpportunity.com

OPPORTUNITY: The only element with an infinite atomic number and weight. An odorless invisible element defined as a hidden or substandard set of circumstances in business that, when not acted upon, creates invisible losses that reduce profit. These losses can be eliminated by management when linked to beliefs, behaviors and numbers that drive the corporate culture, yielding a desirable green substance found in financial institutions.