My 3-Year Study Revealed

Hidden Management Barriers

to Optimization & Change…

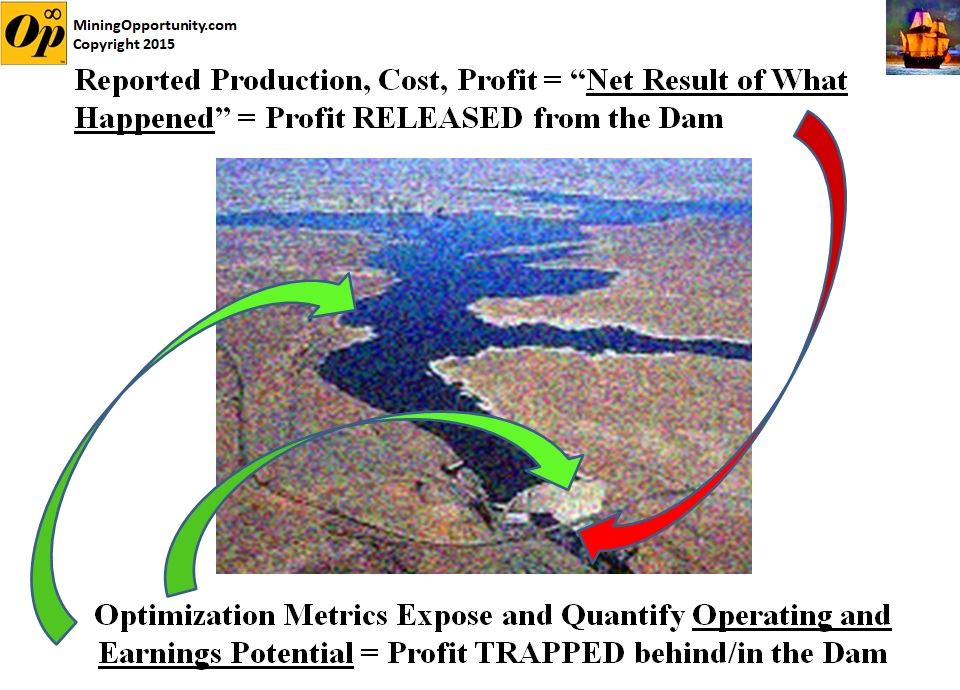

These Barriers Form an Invisible Dam that Traps Profit Behind/Inside It.

What’s Trapped By Your Dam?

BARRIER REMOVAL is the step that PREVENTS YOUR TEAM FROM SETTLING FOR LESS than your equipment and people are capable of achieving!

Creating your optimization metrics dataset for “best possible” IS NOT ENOUGH to deliver and sustain “best” results because weaknesses in your organization and “disconnects” within your management system create barriers that trap the profit potential you and your people identify/quantify.

Strengthening those weaknesses and fixing those disconnects will remove those barriers. Only management has the authority to make those changes.

In Optimization Management, EXECUTIVES and MANAGEMENT TEAMS become DEMOLITION EXPERTS as they remove their barriers to release “trapped” profit and maximize/sustain optimization gains.

This is a VERY DIFFERENT WAY of looking at optimization! It is also a VERY DIFFERENT WAY to MAKE MONEY!

What Prompted My Study of Management Barriers and Bottlenecks?

Over fifteen years ago, I began recognizing patterns as I worked with people in all management levels. All of these patterns involved management – patterns in thought, patterns in behaviors and patterns in choices that made the difference between success and failure with change and optimization. I began studying these patterns because:

- They made everything harder to do.

- They caused bottlenecks in people processes that became accepted as “just the way it is here”.

- Unmeasured financial losses were caused by them… significant losses that could have been stopped or avoided… but weren’t!

Why is this important to think and talk about? As long as the losses continued, companies COULD NOT ACHIEVE their “best possible” performance, even if they bought new equipment and systems to achieve optimization! Stopping the losses involved understanding the root cause of the losses… the invisible barriers within that sabotaged management’s efforts to meet goals and improve performance.

To understand the root causes, I had to step outside my paradigms about change and optimization. I used out-of-the-box thinking to understand the dynamics at work; my journey was exciting and the insights I gained in my study gave me the answers and strategies I was looking for! The following sections summarize just a few of my observations and insights:

Four Management Barrier Groups

“…THERE WERE NOT 20 REASONS WHY WE COULD NOT MAXIMIZE PERFORMANCE. THERE WERE NOT 10 REASONS. THE SAME 4 REASONS WERE THE ROOT CAUSE OF EVERY FINANCIAL SHORTFALL AND FAILURE TO CHANGE… ALL CAME FROM THE SAME SOURCE… FROM INSIDE THE MANAGEMENT SYSTEM.” Kay Sever speaking about Barriers to Optimization and Change at the Hauling and Loading Conference in 2013

As I stated in the above quote, there are four kinds of management barriers… the first three types of barriers “hide” potential profit, “divide” people that need to work together to capture potential profit, or “hinder” change. These barriers form a kind of dam that traps potential profit behind it. If management teams know how to recognize and remove these barriers, they are empowered with information that forever changes their perspectives and ability to influence performance, change and profit generation.

A DISCOVERY – MOABs: During my barrier study, I discovered a fourth kind of management barrier linked to management choices that SIMULTANEOUSLY affects profit, workplace culture and change. I call these barriers “MOABs” (Mother of All Barriers). When management teams learn how to “manage their MOABs”, they can MINIMIZE THEIR RISK OF LOSS, remove the final source of “improvement sabotage” and move to a level of trust, collaboration and credibility that few management teams achieve.

QUESTIONS:

- WHAT IF “DEMOLITION OF BARRIERS” WAS A MANAGEMENT STRATEGY TO MAXIMIZE RESULTS?

- WHAT IF LEADERSHIP TEAMS HAD “PLAYS” FOR REMOVING BARRIERS, SIMILAR TO PLAYS FOR SPORTS TEAMS?

- IF A LEADERSHIP TEAM DEMOLISHED ITS “BARRIER DAM”, HOW MUCH MORE MONEY COULD THE COMPANY MAKE? HOW MUCH LONGER COULD THEY SUSTAIN CHANGE?

I have discovered that REMOVING MANAGEMENT’S BARRIERS TO OPTIMIZATION requires a SHIFT IN THINKING, PRIORITIES AND CHOICES. These shifts are non-negotiable for success with optimization and sustainable optimization management practices and are covered in many OM training modules.

When you see things a different way, YOU CAN NEVER GO BACK TO YOUR OLD WAY OF THINKING! Talking about these shifts is a great place to start your Optimization Journey…

CHANGE YOUR PERSPECTIVE… CHANGE YOUR PERFORMANCE!

Some New Perspectives to Consider when “Best Possible” Performance is the Goal:

OPTIMIZATION AND RACING

I grew up in Indiana and remember listening to the Indianapolis 500 on the radio every year with my family. I still follow the race and even watched it in Lima when I was there on business. One year during the race, I realized that optimization could be like racing…

In auto racing, car owners invest huge sums of money to create the opportunity to win the race. Pit crews train to Six Sigma levels of excellence. On race day, if there is any obstacle on the track, people run out on the track to clear it so the cars can maximize their speed and win the race. In racing, NO BARRIERS ARE ALLOWED!

In companies, we invest millions of dollars in equipment and systems with the intent of “winning” for shareholders. But here’s the difference between racing and change… we start change without removing our barriers. Instead, we hope that barriers will “disappear” during the change process, which doesn’t always happen. Barriers linked to process changes disappear when process improvements are made, but barriers created by management patterns do not.

REMEMBER: Management barriers have NO NATURAL ENEMIES… they must be intentionally removed! Your team must make all barriers “fair game” to achieve and sustain your best performance.

QUESTIONS:

- WHAT WOULD HAPPEN IF YOU TREATED THESE BARRIERS LIKE OBSTACLES ON A RACE TRACK? HOW MUCH MORE MONEY COULD YOU MAKE?

- IF YOU STARTED LOOKING FOR BARRIERS, HOW MUCH FASTER COULD YOU CHANGE?

OPTIMIZATION AND ROCKETS

All rockets before the Saturn V were two stage rockets… one blasted off and the other went up and came down or orbited the earth. Before the Saturn V rocket was designed, astronauts had NO WAY to escape earth’s gravity. The third stage of the Saturn V allowed the astronauts to “ESCAPE” Earth’s gravity and go to the Moon and back. When I stood under the Saturn V at the Cape Canaveral Space Museum, I realized that optimization and the Saturn V had a common theme...

Many experts would say there is one process for optimization… management invests millions of dollars in new equipment and systems designed for optimization. When the equipment goes live, performance is tracked, ROI is reported and management’s role in optimization is considered complete. I call this optimization approach “PLUG & PLAY”… plug in new equipment and wait for the gains to materialize.

There is another optimization approach that DOES NOT REQUIRE CAPITAL for new equipment or systems; instead, it requires active involvement by the entire management team. I call this approach ACTIVE OM (Optimization Management), where the goals are 1) exposing hidden profit potential for equipment, the organization, and the management system and 2) removing the barriers that “trap” potential and constrict the flow of profit onto the income statement.

Stage 3 in the Saturn V enabled the astronauts to “escape” Earth’s gravity… in Active OM, executives and management teams can “escape the barriers” that hide potential and constrict the flow of profit to the bottom line.

OPTIMIZATION AND SPORTS

In football and other team sports, people unite to achieve a single goal: winning. Plays provide strategies to beat other teams and each player has a role in executing those plays. The best teams have winning strategies and players who care more about winning than they do personal recognition. Have you ever considered that optimization can be like sports…

Let’s say that a professional football team is practicing before a big game and the quarterback and running back have a disagreement during practice. Let’s also say that the quarterback is still holding a grudge against the running back when the big game starts. In the final moments of the game, the quarterback has the opportunity to throw the winning touchdown to the running back, but does not want the running back to get credit for the touchdown, so he keeps the ball, is tackled and his team loses the game! Imagine how his teammates would feel… and the fans!!!

This scenario rarely happens in sports, but it happens in companies more than it should. When managers care more about their departments than the needs of the value stream OR when they have disagreements and refuse to work together, it’s like they are playing on opposing teams! These examples involve choices that cost companies money and create a weak corporate culture. The losses linked to these choices are never calculated!

QUESTIONS:

- HAVE ANY OF YOUR DEPARTMENT MANAGERS CHOSEN TO NOT SUPPORT THE NEEDS OF OTHER DEPARTMENTS?

- HAVE YOU BEEN TAUGHT TO ACCEPT WEAK TEAM DYNAMICS AS “JUST THE WAY IT IS HERE”?

- HOW MUCH MONEY ARE YOU LOSING BECAUSE YOUR PEOPLE ARE BEHAVING LIKE THEY ARE ON OPPOSING TEAMS?

<><><><><><><><><><><><><><><>

The following audio contains insights about barriers to change and optimization that I shared with several hundred people at the Loading and Hauling conference in 2013. In it, I talk about why companies fall short of the performance they are capable of achieving and reveal some of the management barriers that are to blame. This information and much more is included in MiningOpportunity barrier removal training sessions.

THE NEXT LOGICAL STEP

It was time to fill a 100-year-old gap in change methodology with a proven system designed to deliver “best possible” results without capital spending! It was time for Kay to design a management training system for capital-free optimization. Its content would:

- Include Kay’s comprehensive knowledge base, proven strategies and tools she used successfully with many clients, and 20+ years of experience with Optimization Metrics and Optimization Management – quantifying hidden losses, “best possible” limits/goals, and strategically linking these metrics to assets, the organization and the management system to remove barriers/bottlenecks that prevent companies from achieving optimization and maximizing profit.

- Teach people how to change the way they work (what they fix, measure and talk about) to remove their FINAL SET OF BARRIERS and achieve “best possible” results without compromising safety or regulatory requirements. They would be MORE EFFECTIVE in meeting budget targets, solving problems, managing projects, meeting customer requirements, building strong working relationships, postponing/avoiding unneeded expansion capital, and changing faster.

MiningOpportunity was Born!

- MiningOpportunity is the WORLD’S FIRST CAPITAL-FREE OPTIMIZATION SYSTEM for management teams.

- Designed to deliver site-wide/company-wide optimization with the equipment and people already in place.

- You Cannot Wait One More Day For This Kind of Training!

- MiningOpportunity delivers More Money, Fewer Problems, Happier People and Faster Change!

It’s Time for YOUR LEADERS to become DEMOLITION EXPERTS!

It’s Time to CLEAR THE TRACK so you can WIN THE RACE TO OPTIMIZATION!

It’s Time to ESCAPE THE BARRIERS that are HOLDING YOU BACK!

OPPORTUNITY: The only element with an infinite atomic number and weight. An odorless invisible element defined as a hidden or substandard set of circumstances in business that, when not acted upon, creates invisible losses that reduce profit. These losses can be eliminated by management when linked to beliefs, behaviors and numbers that drive the corporate culture, yielding a desirable green substance found in financial institutions.