MiningOpportunity

Optimization Training/Coaching

Your Pathway to “Best Possible” Results and Capital-Free Optimization

A “Mining Process” for Upside Potential

LIVE STREAM – No Travel, Interactive, Flexible Schedule

PROVEN METHODS…NO FLUFF…COMMON SENSE APPROACH…HONEST FEEDBACK

What works and doesn’t work when it comes to achieving and sustaining BEST POSSIBLE performance.

MiningOpportunity is an Unforgettable Executive/Management Team Education/Development Program that “Takes the Invisible Lid Off of Performance” at Your Sites/Company… Makes “Best Possible” a Measurable Reality

MiningOpportunity is an Unforgettable Executive/Management Team Education/Development Program that “Takes the Invisible Lid Off of Performance” at Your Sites/Company… Makes “Best Possible” a Measurable Reality

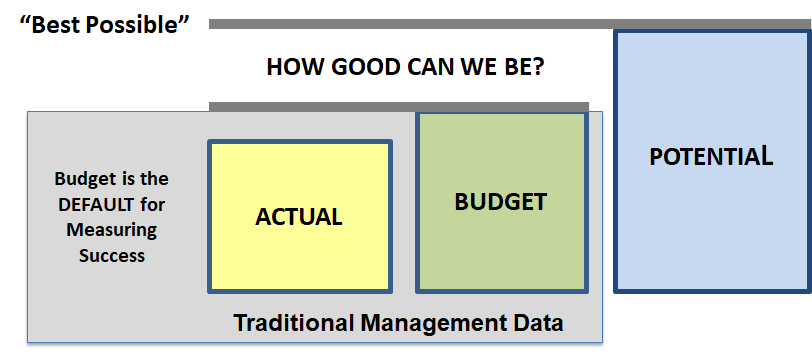

You will learn how to Optimize Performance by Finding and Fixing “Optimization Disconnects” in your Operational, Organizational and Decision-Making Processes. These disconnects exist because traditional operational/organizational/decision processes were never designed to measure or drive “best” results. These disconnects cause millions of dollars in hidden losses… your invisible upside potential… what you could have achieved but didn’t. Fixing these disconnects stops these losses and positions a company to achieve and sustain “best possible” results/optimization for the long term.

This One-Of-A-Kind Interactive Experience will give your executives and management teams new perspectives, processes, skills and power to help you achieve and sustain a new level of performance. You will never want to go back to your old way of thinking and working after learning how to quantify your hidden losses, connect the company to metrics/standards for “best” results, and remove barriers that prevent equipment and people from doing their best work. Your optimization journey starts with the numbers… find out how much profit you are leaving on the table… It’s Time to Explore for More!

A NOTE FROM KAY: On this exploration voyage, I will be your navigator and coach and your team will be the captain and crew of the ship. You will be in uncharted waters as we explore for hidden losses and upside potential, but never fear… we will follow a proven optimization process and will have fun along the way. We will all be in the same “optimization boat”, which means we will be doing a lot of things together and depending on each other for success.

MiningOpportunity Training – 2 Modules, 5 Parts

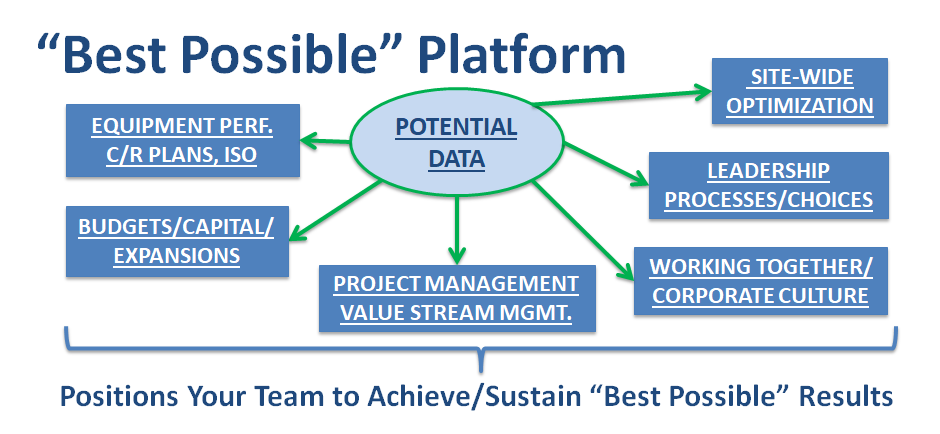

FOR EXECUTIVES AND SITE MANAGEMENT TEAMS: A management education/development program that positions a company to tap into their hidden upside potential (the dollars they are leaving on the table). With new perspectives, data, strategies, skills and tactics, executives and management teams can “measure and manage” differently to capture and convert their hidden losses to earnings with a goal of bringing their reserve of profit potential to zero and stopping future losses.

OPTIMIZATION METRICS MODULE – Learn how to find and quantify your upside potential… the hidden losses/capacity NOT REPORTED by your financial system. Learn how to prioritize, track, analyze and communicate those losses, how to manage your process of discovery, and how to keep exploring for losses year after year.

OPTIMIZATION MANAGEMENT MODULE – Learn how to align and upgrade your management processes for equipment, the organization and decision-making with standards for “best” performance. Connect optimization metrics to management processes/practices and working relationships. Set standards for “best” across the company. Remove barriers and fix problems that stand in your way. TURN ON THE POWER: Alignment gives your executives and management teams the power to achieve and sustain “best” results into the future… no capital required.

Setting Sail – Learning the Ropes

On sailing ships of old, the captain and crew “knew the ropes”… which ropes to tighten and loosen to keep the sails aligned with the wind, avoid storms and move in the direction they wanted to go. Knowing the ropes was mandatory for sailing. Likewise, knowing the ropes for Capital-Free Optimization is mandatory for success. On your optimization journey, you will “learn the ropes” – insights, strategies, tools and tactics designed to create a pathway to achieving and sustaining “best possible” results.

PART 1: OVERVIEW – Expectations for Your Journey

Your training begins with a 10,000 foot view of your journey: what to look for, surprises you may discover, hazards that can stop your progress, changes you will experience along the way, and what your destination looks like.

- REVIEW of the content of both modules: OPTIMIZATION METRICS and OPTIMIZATION MANAGEMENT

- DEFINITIONS, PERSPECTIVES, NUMBERS, BARRIERS/BOTTLENECKS, TURN ON THE POWER with ALIGNMENT, SUSTAINING GAINS.

PART 2: OPTIMIZATION METRICS MODULE – QUANTIFYING YOUR UPSIDE POTENTIAL

We will start by looking for what you are losing… profit that your equipment and people are capable of generating… but didn’t! You will practice finding, calculating and analyzing your hidden losses real-time, reach agreements on rules for setting values used in calculations, learn how to manage your “Discovery Process”, and learn how to chart and communicate trends.

TOPICS COVERED:

- Mathematical Proof That Invisible Operating/Profit Potential Exists

- Finding/Valuing Hidden Losses, Connecting Metrics to Performance and Cause of Losses

- Establishing Targets for “Best”, Interpreting Trends

- Communicating Hidden Losses/Capacity Visually and Orally

- Managing the Discovery Process

PARTS 3-5: OPTIMIZATION MANAGEMENT MODULE – TURNING ON THE POWER

PART 3: “HAZARD TRAINING” FOR OPTIMIZATION – Barrier Awareness Training, Minimizing Risk of Loss

With metrics linked to your hidden losses and cause, it’s time to gain the skills and tactics designed to remove the barriers and weaknesses that stand in your way… barriers and weaknesses related to asset management, organizational management and management team perspectives and processes… your “final frontier” of barriers.

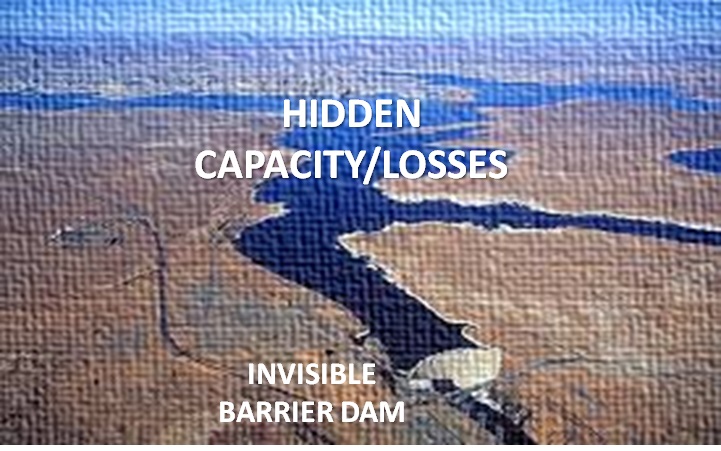

Quantitative and qualitative invisible barriers are preventing you from achieving your “best” performance right now! Some barriers involve data voids, some involve people…words, actions, communications, choices… the way people work together. Some involve management processes/practices that unintentionally divide people and steal profit. These barriers exist in many companies and have been reducing profit for years from behind the scenes. Raising awareness about these barriers 1) creates a comfort zone for discussing them and 2) changes what your team is willing to accept as normal or unchangeable.

A MINING ANALOGY: Some of your barriers are like OVERBURDEN… overburden hides/covers valuable ore… once removed, the ore is exposed and can be mined. Barrier removal is much like that. Barriers hide or trap profit potential. Once you remove them, you have access to that potential and can convert it to reported profit.

BARRIER AWARENESS TRAINING will help you recognize, avoid and remove your barriers. Your team will become “demolition experts” as you tear down your barrier dam. (See my 3-year barrier study page for details about management’s barriers to optimization and change).

- Your Barrier Dam – What’s Holding You Back – What HIDES Potential, What DIVIDES People, What HINDERS Change

- MOABs (Mother of all Barriers) – Barriers that Simultaneously Affect Profit, Culture, Change, Team Interaction

- Improvement Sabotage – Definition, Examples (Baggage Exercise, Personal Power vs Team Power)

- Minimizing Your RISK OF LOSS – Truth, Trust and Tons, Culture Engine, Managing MOABS – Situational Awareness Training, Team Interaction

PART 4: ALIGNMENT – Upgrade with Metrics and Standards for “Best” Performance, Remove Barriers that Stand in Your Way

You now know how to develop metrics for hidden losses and upside potential and you have a new awareness of barriers that trap profit and prevent change. It’s time for ALIGNMENT: Gaining the skills, strategies and tactics for removing barriers/weaknesses in asset management, organizational management and management team perspectives and processes AND setting new measurable standards for excellence across the organization.

Each of the boxes below can contain these barriers/weaknesses. Some of them may be stealing millions of dollars/year from you right now without your knowledge. Together we will explore each box and its inter-departmental touchpoints. We will talk about WHAT’S NOT WORKING, the why and what to change to fix that.

ALIGNMENT is all about

- Agreeing what “best” looks like (i.e., setting new standards for “best”) in your organization.

- Uniting your people under a shared vision for “best” that they can quantify.

- Giving your executives/management teams the power to fix what could not be fixed before.

- Giving your people the tools they need to minimize losses everywhere.

- Making it possible for everyone to achieve and sustain optimized performance over the long term.

PART 5: TRAIN TO SUSTAIN – Strategies/Tactics for Sustaining Your Team’s Learnings and Financial Gains for the Long Term

Passing on what your team learns in this training is essential to maintaining “best possible” levels of performance into the future. It is NOT HARD to strategically insert basic optimization metrics concepts and calculations into in-house training programs. This step insures that all new employees will be introduced to your company’s standards for measuring, managing and working at “best possible” levels. As employees are promoted or move to new jobs around a site or company, they can easily understand and apply those concepts in other departments or in manager positions. We will take a common sense approach that fits your training model.

<><><><><><><><><><><><>

NEW OFFERING: Join the EXPLORER’S CLUB – More Info Coming Soon!

<><><><><><><><><><><><>

Spend a Day with Kay – Annual Refresher – Great for refresher training or an annual retreat as part of your sustainability plan. After establishing your “Best Possible” Platform, meeting once a year lets us reconnect, assess your progress and provide targeted support for the specific issues you may be struggling with. Can be More Than One Day, for existing clients.

We can do One Day per site, One Day per division… We will plan the number of days we need together before we meet. You set the agenda. Any question related anything we covered in any of the training sessions is OK. You select the attendees. Depending on the issues, I may suggest that additional people participate for certain parts of our discussion. Our goal is to SOLVE AS MANY OF YOUR PROBLEMS AS POSSIBLE so you can sustain your gains and avoid backsliding.

OPPORTUNITY: The only element with an infinite atomic number and weight. An odorless invisible element defined as a hidden or substandard set of circumstances in business that, when not acted upon, creates invisible losses that reduce profit. These losses can be eliminated by management when linked to beliefs, behaviors and numbers that drive the corporate culture, yielding a desirable green substance found in financial institutions.